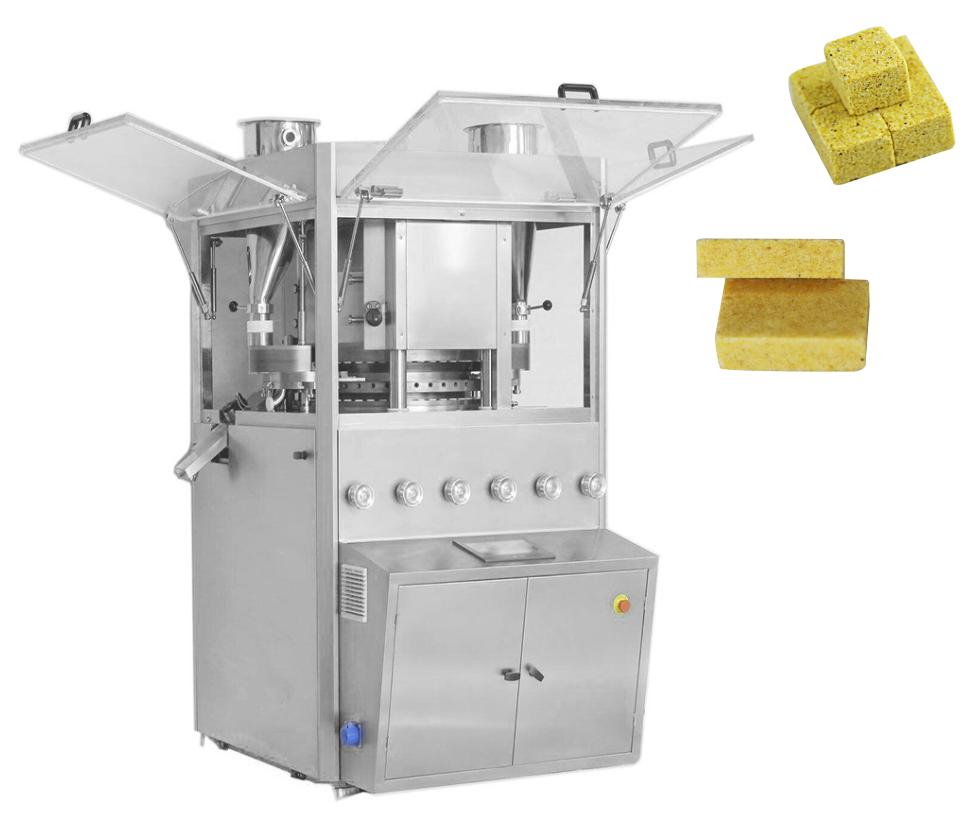

ZP475-9K 200gram Chlorine tablet press tcca tablet press machine with a large pressure up to 250KN

Features

● It is particularly suited for production of disinfectant tablets from viscous, corrosive and abrasive.

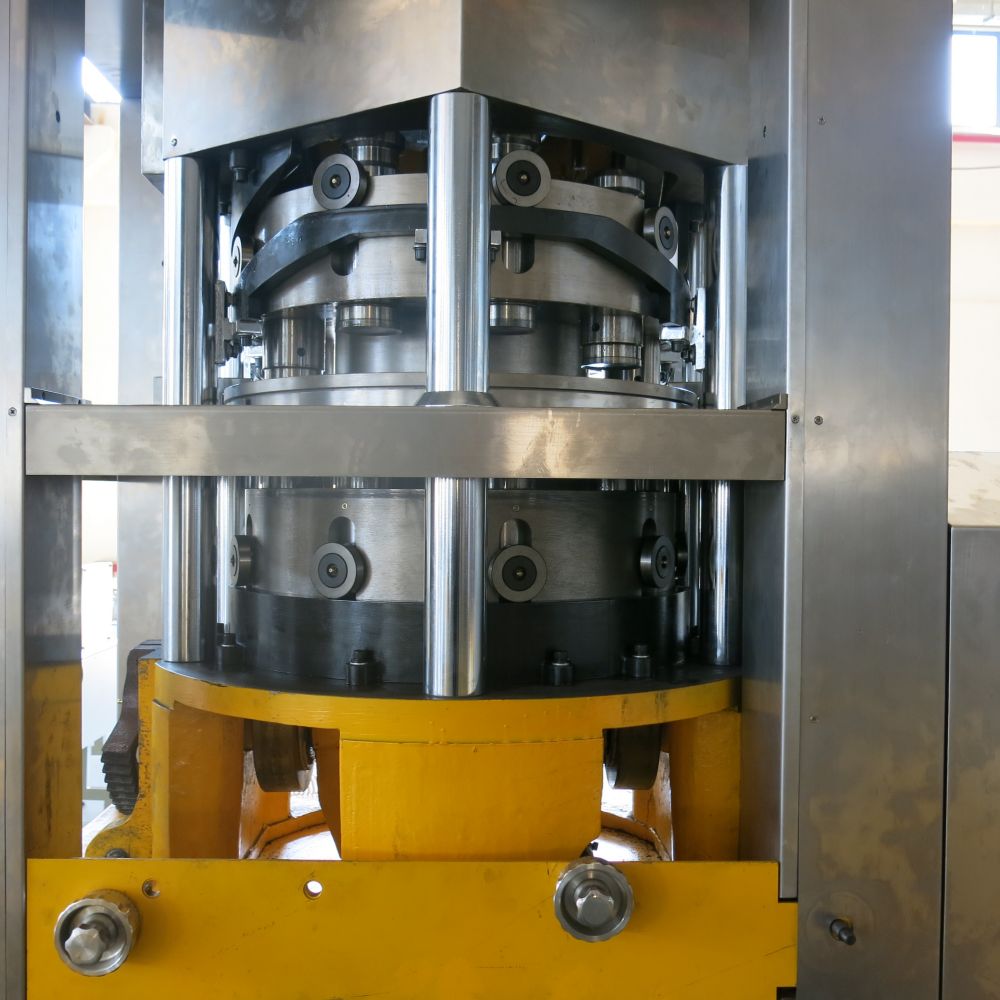

● Robust design and excellent reliability for durability.

● Special design of upper and lower punches for a perfect processing of hard-to-handle products.

● Turret by anti-rust treatment for suiting with chlorine raw material.

● With protection system if pressure is overload.

● With punches broken protection system.

● Speed be adjusted by inverter with brand of Danfoss.

● Four columns frame for a lifetime working.

Video

Specification

|

Model |

ZP475-9K |

|

Number of punch stations |

9 |

|

Max.Pressure |

250 KN |

|

Max. diameter of tablet(mm) |

76 |

|

Max. thickness of tablet(mm) |

26 |

|

Depth of filling(mm) |

50 |

|

Turret speed (RPM) |

5-10 |

|

Capacity(pcs/hour) |

2700-5400 |

|

Motor motor power (Kw) |

30 |

|

Machine size (mm) |

1800*1400*2370 |

|

Weight (Kg) |

6700 |

Highlights

● 2Cr13 stainless steel of middle turret for anti-rust.

● Titanium punches that preservative and durable.

● Double compression force station with compression force, each station with 250KN.

● Main motor with power of 30KW that strong and powerful.

● With force feeding filling system by a high performance for poorly flowing materials.

● Upper punch with dust sealer which avoid powder pollution.

● Material contact part by anti-rust treatment.

● Independent cabinet for optional, that avoid powder pollution.

To help customer with their Tablet Production Line,we also supply packaging machine for 5 pcs per bag and one pcs per bag. You can find more information at our products list of Cube Packing Solution.

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top