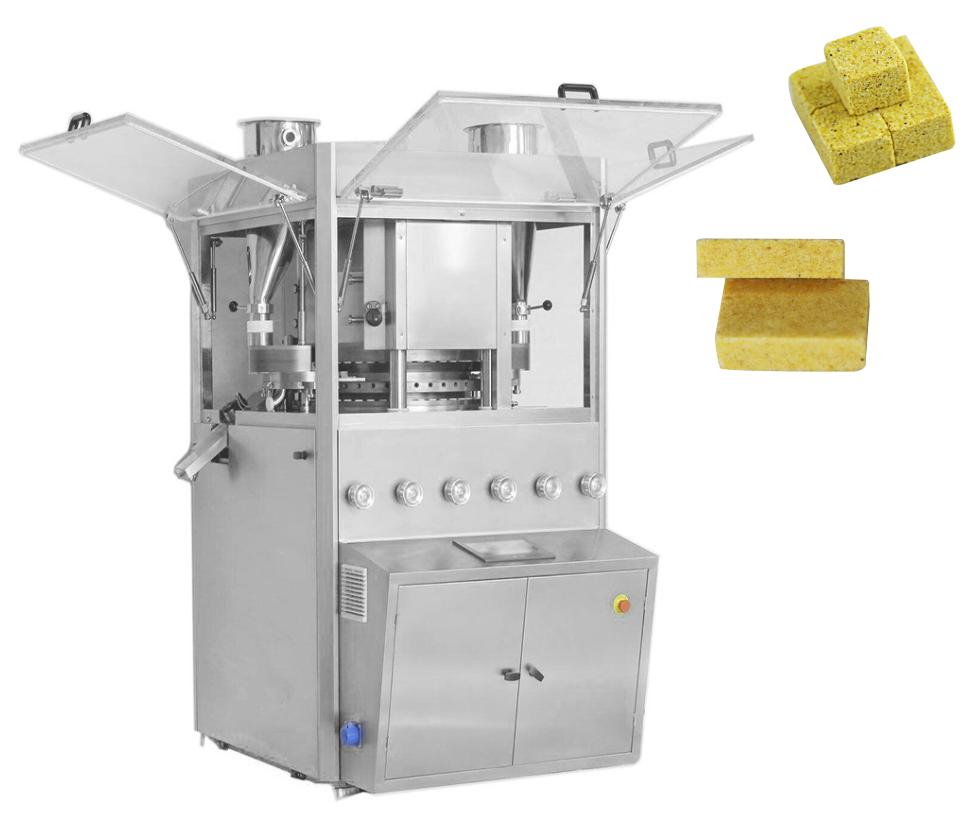

High speed chicken cube production line tablet press for 4g/10g Seasoning cube machines

Features

•Peripheral casing is closed form which is made of all stainless steel,internal mesa adopt stainless steel material,it can keep the surface glossy and prevent cross contamination and meet G.M.P requirement.

•It is equipped with organic glass windows,visual tablet state,all of the side plate can turn on and clear up and maintenance is easy.

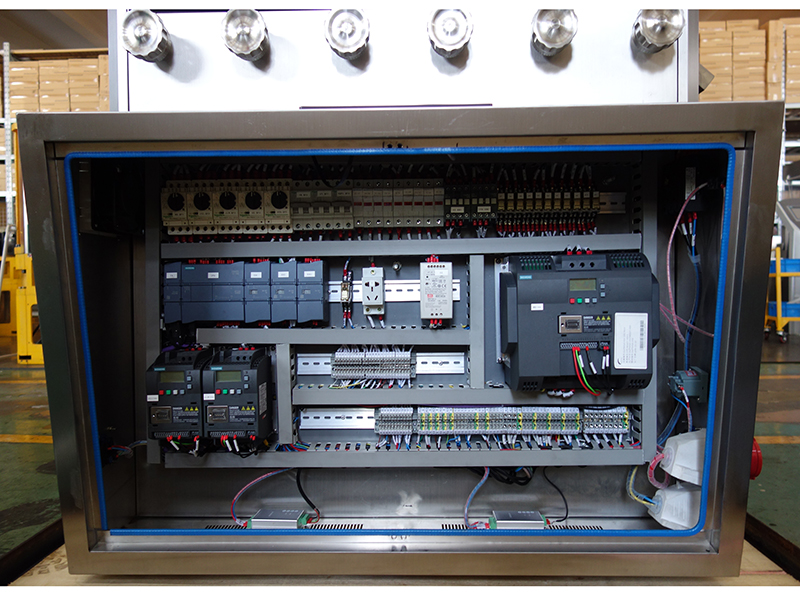

•All controller and operating parts are rational layout.

•It is equipped with variable frequency speed control device for electrical control.convenient operation,steady running,it is safe and accurate.

•It is equipped with overload protection device,when pressure overload,it can stop automatically.

•It is the mechanical and electrical integration has touch key and screen display.

•Be the leader in trying to use semi-automatic lubrication device and the top of rotary tablet is epuipped organic glass dust prevention device.

•Transmission system is sealed on the main tank below,is a safe separation of independent components,also has no cross pollution ,and transmission of infiltration in the oil pool,easy to has heat output and also it is wearable.

•It is equipped with powder absorbing device,can absorb indoor dust.

Main specification

|

Model |

GZPK620-45 For 4g |

GZPK620-31 For 10g |

| Number of Stations |

45 |

31 |

| Main pressure (kn) |

100 |

100 |

| Pre-pressure (kn) |

16 |

16 |

| Turret speed (rpm) |

5-35 |

5-35 |

| Production capacity (pcs/minute) |

18600-130200 |

27000-189000 |

| Max tablet diameter (mm) |

25 |

40 |

| Max tablet thickness (mm) |

14 |

10 |

| Main motor power (db) |

≤75 |

|

| Power (kw) |

11 |

|

| Voltage (V) |

will be customized |

|

| Dimension (mm) |

1400*1500*1900 |

|

| Weight (kg) |

3300 |

|

Detail photos

Sample tablet

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top