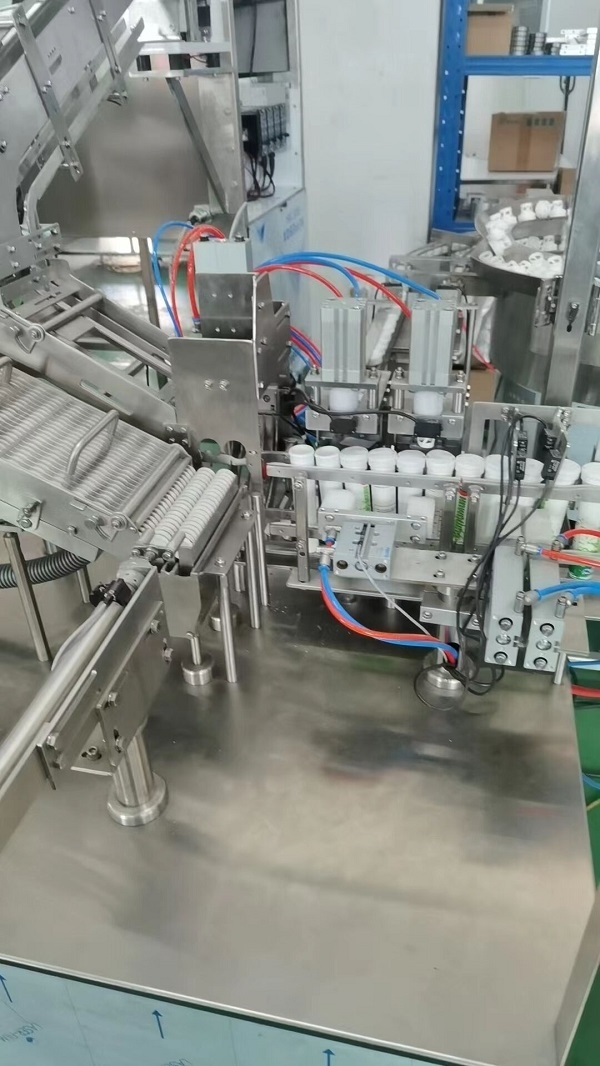

Effervescent Tablet Counting Machine

Features

1.Cap vibrating system

Loading cap to hopper by manual, automatically arranging cap to rack for plugging by vibrating .

2.Tablet feeding system

3.Put tablet into tablet hopper by manual, the tablet will be sent into the tablet position automatically.

4.Filling in tubes unit

Once detect there has tubes, the tablet feeding cylinder will push the tablets into tube.

5.Tube feeding unit

Put tubes into hopper by manual, the tube will be lined into tablet filling position by tube unscrambling and tube feeding.

6.Cap Pushing unit

When tubes get tablet, cap pushing system will push cap and close that automatically.

7.Tablet rejection unit

Once the tablets in tube is lack of 1pcs or more, the tube will be rejected automatically. If no tablets or tubes, machine will not capping.

8.Electronic Control Section

This machine is controlled by PLC, cylinder and stepper motor, it is with automatic multi-function alarm system.

Parameters

|

Model |

TWL-80A |

| Capacity |

80 tubes/minute |

| Voltage |

by customized |

| Power |

2KW |

| Compressed air |

0.6MPa |

| Machine dimension |

3200*2000*1800mm |

| Machine weight |

1000kg |

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top