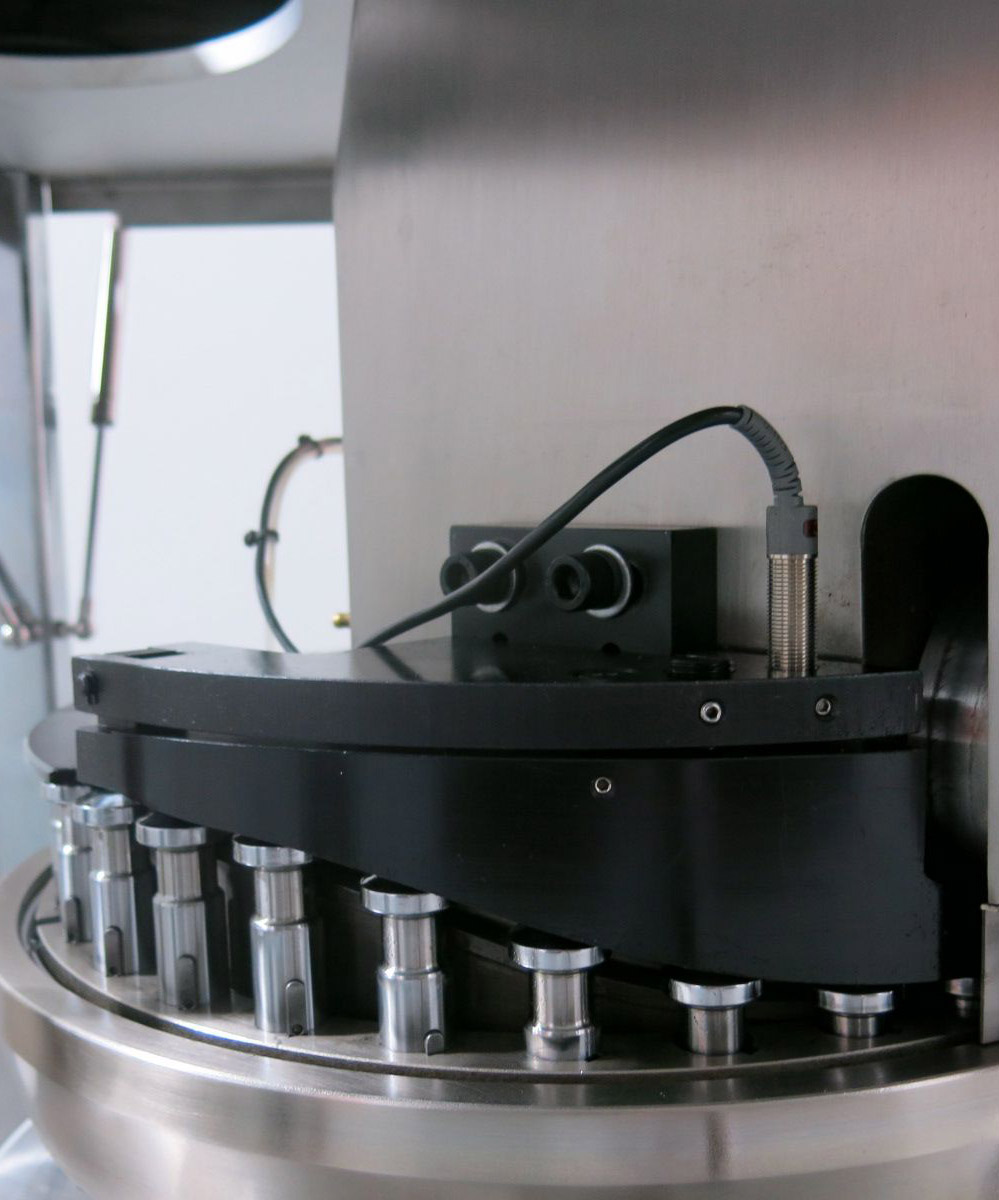

GZPK265 Small footprint high speed pills making machine vitamin tablet compression machine

Features

1. Main pressure of 100KN and Pre-Pressure of 14KN.

2. With touch screen and hand wheels operation.

3. Force feeder consists of double paddle and impellers with central feeding which guarantee the flow of powder and ensures the accuracy of feeding.

4. With tablet weight automatic adjustment function.

5. Tooling parts can be freely adjusted or removed which is easy for maintenance.

6. Main pressure,Pre-Pressure and feeding system all adopt modular design.

7. The upper and lower pressure rollers are easy to clean and easy to disassemble.

8. Machine is with central automatic lubrication system.

9. It is equipped with safety door function.

10. The main drive system, lubricating system, and handwheel adjustment mechanism are completely sealed by the left and right door panels, rear door panels and control cabinet through sealing strips to prevent dust from polluting the machine.

11. The tablet pressing room and the lubricating room are completely separated, and use stainless steel outer cover. The fully enclosed structure solves the pollution problem of the turntable parts, and fully complies with the requirements of GMP production specifications.

Video

Specification

|

Model |

GZPK265-16 |

GZPK265-23 |

GZPK265-30 |

|

|

Number of punch stations |

16 |

23 |

30 |

|

|

Punch type |

D EU1"/TSM 1" |

B EU19/TSM19 |

BB EU19/TSM19 |

|

|

Punch shaft diameter |

mm |

25.35 |

||

|

Die diameter |

mm |

38.10 |

||

|

Die height |

mm |

23.81 |

||

|

Turret rotation speed |

min.-max. |

13-100 |

||

|

Max. output |

Tablets/h |

96000 |

138000 |

180000 |

|

Max.Pre pressure |

KN |

20 |

||

|

Max.Main pressure |

KN |

100 |

||

|

Max.Tablet diameter |

mm |

25 |

16 |

13 |

|

Max.Filling depth |

mm |

20 |

||

|

Pitch circle diameter |

mm |

265 |

||

|

Power |

kw |

5.5 |

||

|

Dimensions of tablet press |

mm |

700*1000*1750 |

||

|

Weight |

Kg |

1200 |

||

|

Electrical supply parameters |

Operating voltage will be customized |

|||

Highlight

● Max.turret speed up to 100RPM.

● Main pressure and Pre-pressure, tablets affected by two times pressure.

● 2Cr13 stainless steel for middle turret for anti-rust.

● With automatic rejection for unqualified tablets.

● Equipped with central lubrication system so machine can keep working and each part can be well lubricated.

● Easy replacement of all components and wearing parts.

● Servo motor drive to guarantee tablet size and weight accuracy.

● With extra filing rails for different thickness tablet.

● Match up with 21 CFR Part 11.

● Complies of CE.

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top