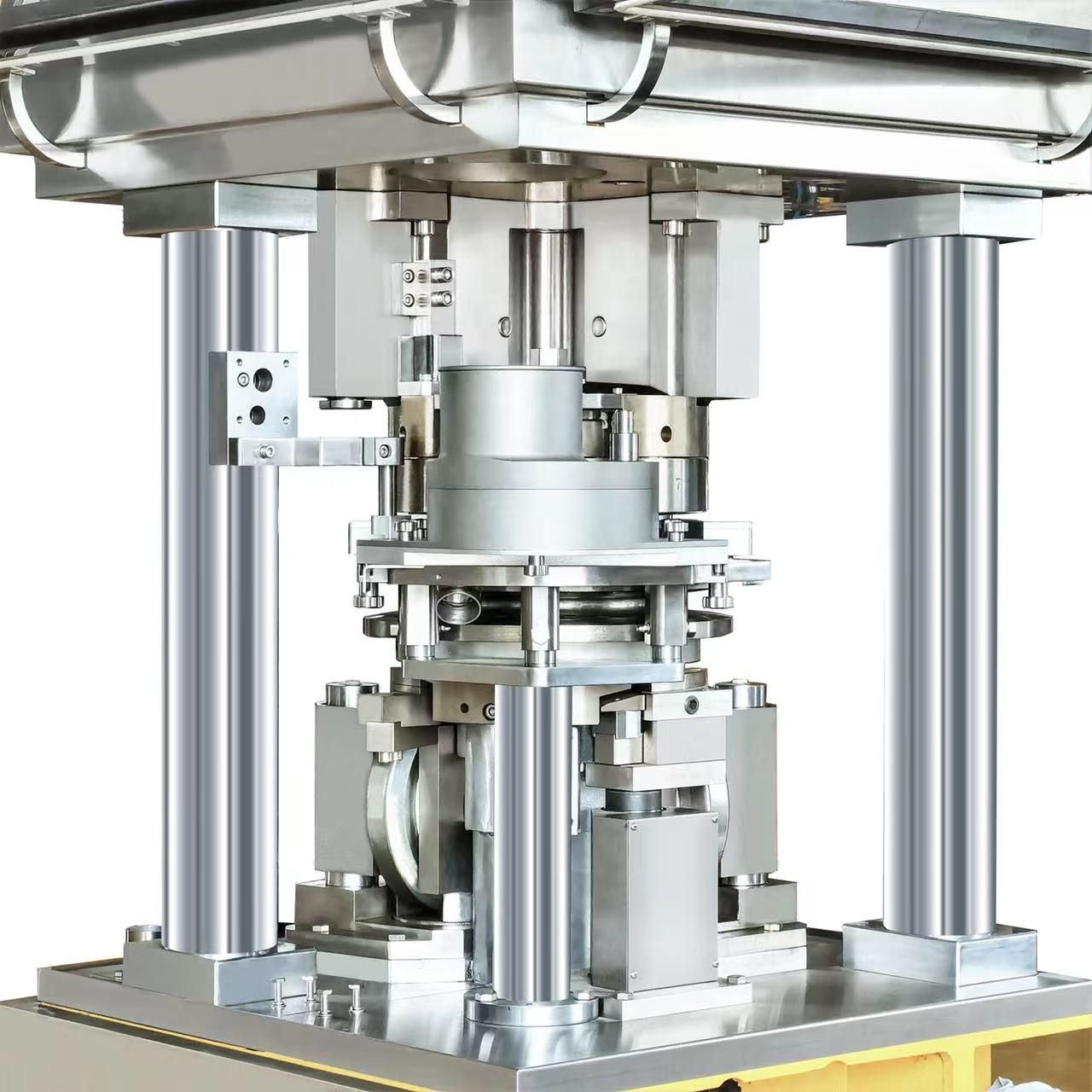

GZPK280 Automatic small tablet press for R & D with a turret exchange design /pre and main pressure both are 100KN

features

1. 2Cr13 stainless steel for middle turret. The surface hardness can reach HRC55 with a good hardness, wear resistance and corrosion resistance.

2. The upper punch plate is QT600, coated with nickel and phosphorus to avoid rust. It is wear resistant and lubricant.

3. The end face runout of middle turret is 0.03 or less.

4. Lower punches damping adopt permanent magnetic damping. Lower punch will not touch with damping pin that can prolong the working life of punches.

5. The frame of tablet press is of three-column frame structure. The three columns, the base plate and the top plate form a rigid body, which has the characteristics of stability, firmness and pressure resistance. Machine running under a smooth operation.

Video

Specifications

|

Model |

GZPK280-20 |

GZPK280-24 |

GZPK280-30 |

|

Number of Punches stations |

20 |

24 |

30 |

|

Punches Type |

D EU1"/TSM 1" |

B EU19/TSM19 |

BB EU19/TSM19 |

|

Max. Main Pressure(kn) |

100 |

100 |

100 |

|

Max. Pre-presuure (kn) |

100 |

100 |

100 |

|

Max. Tablet Diameter(mm) |

25 |

16 |

3-13 |

|

Max. Filling Depth (mm) |

20 |

20 |

20 |

|

Max. Tablet Thickness(mm) |

8 |

10 |

10 |

|

Turret Speed (r/min) |

22-110 |

||

|

Output(pcs/h) |

26400-132000 |

31680-158400 |

39600-198000 |

|

Main Motor Power(kw) |

7.5 |

||

|

Machine Size (mm) |

900*1160*1875 |

||

|

Electric Box Size |

890*500*1200 |

||

|

Machine Weight (kg) |

2500 |

||

Highlight

● With replaceable turret for varies size tablets.

● Punches with oil rubber and dust sealer which avoid pollution.

● With two sets of lubrication system for oil.

● No need to change Tooling, turret can be easy take out.

● The filling rails has number automatic identification function, if the guide rails installation is wrong, there has alarm function. Different rails have different location protection.

● For hard pressing material, can use big Pre-Pressure for forming, and the main roller ensures tablet won't bounce back.

● Powerful function of parameter saving and use function, through 10 actuators. The all set positions and speeds can be saved, also can be use directly when next production.

● The upper and lower rollers are easy to clean, convenient to disassemble which is more easy for cleaning and maintenance.

● There has fan installed at bottom transmission area which keeps transmission area is in a state of positive pressure.Powder will not enter the transmission area which is easy for clean.

● The upper and low rollers are easy to clean, convenient to disassemble which greatly reduce the difficulty of cleaning and maintenance.

Large Area Force Feeder With Impeller

Detailed Image

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top