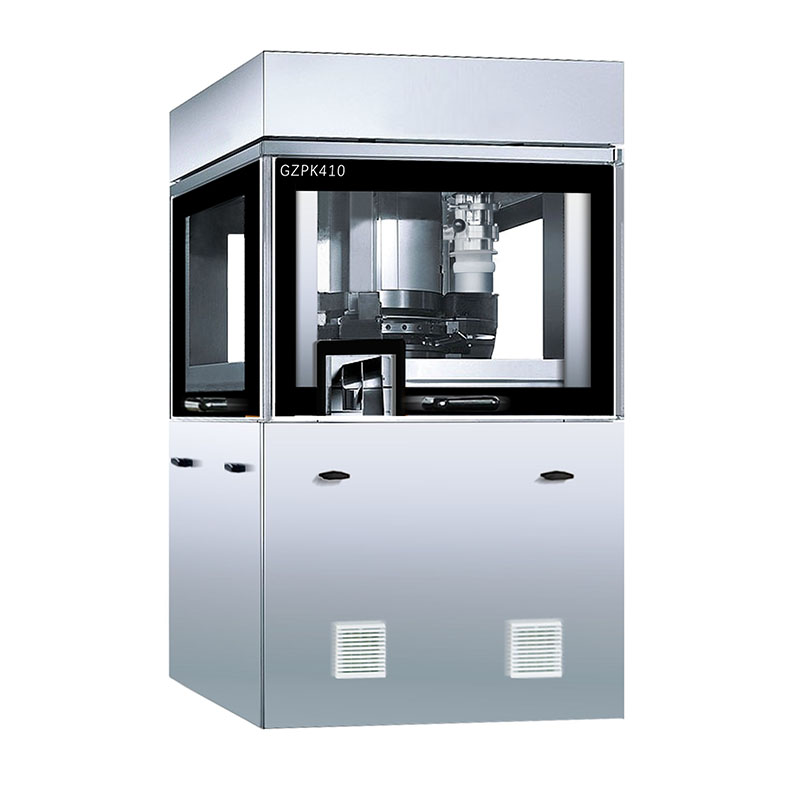

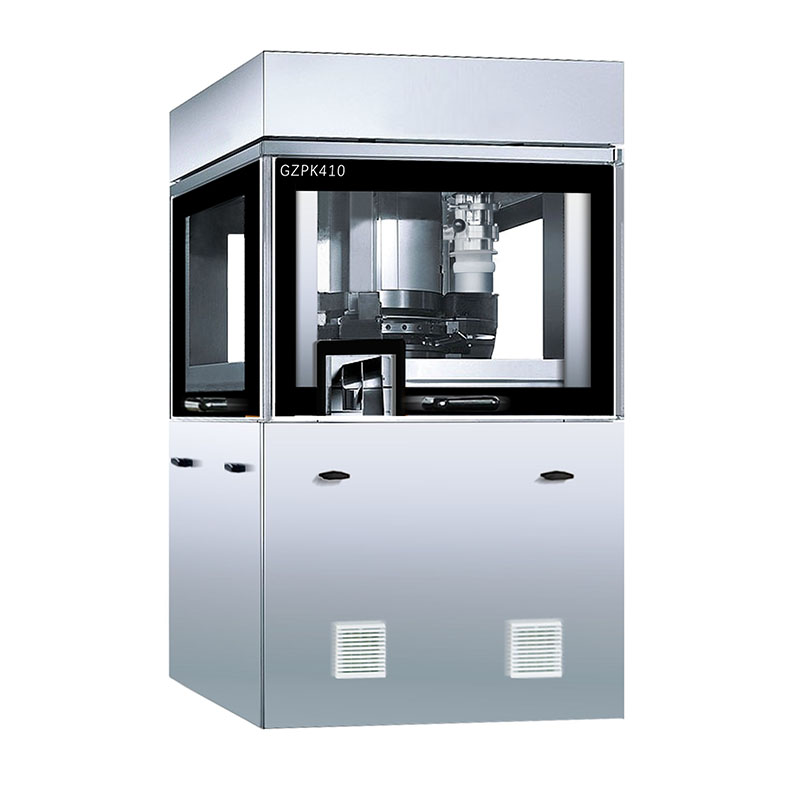

NEW Model Automatic single layer high speed Tablet compression machine

Descriptive abstract

GZPK410 series fully automatic high-speed tablet press has a unique pressure wheel design and control and detection mechanism. Simple operation can quickly replace the punching plate, so that different tablet diameters and tablet types can be achieved on the same machine without any changes. It's a high efficiency machine that also shortened cleaning and maintenance time.

Highlight

1.With replacement turret.

2.Double sided high speed tablet press for a mass production.

3.Excellent performance for difficult-to-form materials.

4.Dust collection mechanism with 5 layer structure.

5.It can make single layer and double layer tablet.

6.With tablet sampling function for 1st layer tablet when making bi-layer tablet.

7.Automatic rejection systemfor unqualified tablet.

8.Automatic adjustment of hardness,filling depth and pre-compression.

9.Automatic rejection system for unqualified tablet.

10.Columns are durable materials made from steel.

11.Machine is with independent electrical cabinet and operation cabinet effectively avoid powder pollution.

12.Force feeder consists of three paddle double-layer impellers with central feeding which guarantee the flow of powder and ensures the accuracy of feeding.

13.Equipped with ejection force control for the lower punches.

14.Recipes storage function for a varies range of products under no adjustment.

15.With a central automatic lubrication system, including upper andlower punch head and internal shank lubrication.

16.Production information can be saved to USB by pictures.

17.Continuous monitoring of all primary and secondary pressureparameters for rollers, ejection force, and monitoring and single pressure diagram of pines.

18.External printer available that to print out each page parameters.

19.Machine comes with complete documents of IQ OQ PQ SAT FAT andCE.

20.Remote settings function (optional).

21.Electronic signature function that complies 21 CFR PART 11 (optional).

Features

1.Low noise < 70 db.

2.With safe door function.

3.Main pressure,Pre-Pressure and feedingsystem all adopt modular.

4.Pressure is measured directly by force transducer.

5.The upper and lower pressure rollers are easy to clean and easy to disassemble.

6.With a closed discharge chute to a metal detector and de-duster.

7.Tooling parts can be freely adjusted or removed which is easy for maintenance.

8.Main pressure roller and Pre-pressure roller are same dimension that can be used interchangeably.

9.Both main pressure wheel and Pre-pressure wheel are adjusted by synchronous motors for a fast adjustment high precision.

10.The middle turret material is 2Cr13, the surface hardness can reach above HRC55. It has good hardness, wear resistance and corrosion resistance.

11.All filling rails curves adopt cosine curves, and lubricating points are added to ensure the service life of guide rails. It also reduces the wear of punches and noise.

12.All cams and guide rails are processed by CNC .

13.Monitor the pressure and deviation of each group of punches, the amount of quality tablets, unqualified tablets and working time, also the total running time of the machine.

14.Protection functions as below:

● Protection for machine and feeder motor overcurrent overload;

● Main pressure and pre pressure overload protection;

● Over-tight protection for upward stroke and downward stroke'

● Protection of installation position of tablet weight adjustment device;

● Block protection;

● Oil level protection;

● Door and window opening protection;

● Single punch continuous out-of-tolerance protection;

● Continuous over-tolerance protection of tablet weight;

● Adjustment times out-of-tolerance protection.

Main Specification

|

Model |

GZPK410 |

|||

| No.of punch stations | 30 | 36 | 43 | 47 |

| Punch type |

D EU1’’/TSM1’’ |

B EU19/TSM19 |

BB EU19/TSM19 |

BBS EU19/TSM19 |

| Main compression (kn) | 100 | |||

| Pre compression (kn) | 100 | |||

| Max.turret speed (rpm) | 100 | 120 | 120 | 120 |

| Max. Output (pcs/h) | 180000 | 250000 | 300000 | 330000 |

| Max. tablet diameter (mm) | 25 | 16 | 13 | 11 |

| Max.filling depth(mm) | 18 | |||

| Total Power(kw) | 13 | |||

| Pitch circle diameter (mm) |

410 |

|||

| Weight (kg) |

4000 |

|||

| Dimensions of tablet press machine (mm) | 1200*1450*2010 | |||

| Dimensions of cabinet (mm) | 890*500*1200 | |||

| Dimensions of electrical cabinet (mm) | 1000*800*1100 | |||

|

Power supply |

380V/3P 50Hz*can be customized | |||

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top