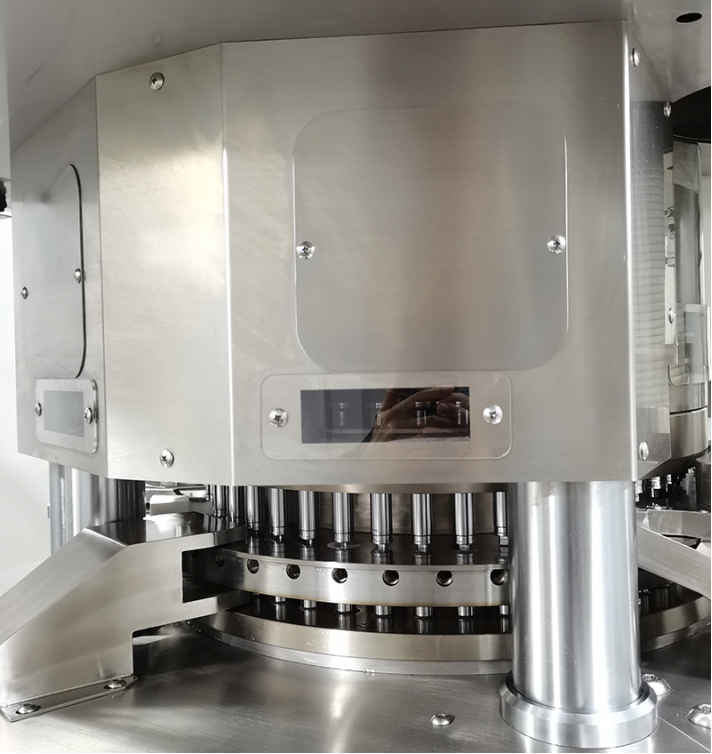

GZPK550 Large pressure tablet pill press machine with 39 stations EUD Tooling

Features

● All stainless steel of SUS304 material.

● Double sides equipped with fully closed force feeders for GMP.

● Punches installed with oil rubber which avoid oil pollution.

● Fully closed windows keep a safe pressing room.

● Pressing room is complete separated with the driven system to ensure non-non-pollution.

● Drive system is sealed in turbine box.

● With handwheels and touch screen operation.

● Machine is easy to operate and maintenance.

● Automatic rejection function for unqualified film tablets (optional).

● Fully automatic and no handwheels operation(optional).

Specifications

|

Model |

GZPK550 |

|||

|

Number of punch stations |

39 |

47 |

57 |

61 |

|

Punch type |

D EU1’’/TSM1’’ |

B EU19/TSM19 |

BB EU19/TSM19 |

BBS EU19/TSM19 |

|

Max.diameter of tablet (mm) |

25 |

18 |

14 |

11 |

|

Max.depth of filling (mm) |

15 |

|||

|

Max.Turret Speed (RPM) |

48 |

|||

|

Max. Capacity (Pcs/h) |

224640 |

270720 |

328320 |

351360 |

|

Max. Main pressure (KN) |

100 |

100 |

100 |

100 |

|

Max. Pre- pressure (KN) |

100 |

100 |

100 |

100 |

|

Voltage |

AC 380V/50HZ/3P |

|||

|

Main motor power(KW) |

11KW |

|||

|

Machine dimension(MM) |

2070*2060*2010 |

|||

|

Machine weight(MM) |

3000 |

|||

Highlight

1.Six columns are durable materials made from steel.

2.Main pressure and pre pressure both are 100KN for a perfect powder forming.

3.Main motor with power of 11KW which is powerful.

4..2Cr13 stainless steel material for middle turret.

5.Punches material free upgraded to 6CrW2Si.

6.It can make double layer tablet.

7.Middle die’s fastening method adopt side way technology.

8.Automatic lubrication system for thin oil.

9. With overload protection and safety door.

9.Top and bottom turret made of ductile iron with high-strength.

10.Free customized service based on customer’s product specification.

11.Can be 24 hours continuously working.

12.Spare parts in stock and all made by us.

13.Turret can be equipped with dust sealer (optional).

14. Can be equipped with automatic tablet rejection(optional).

Video

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top