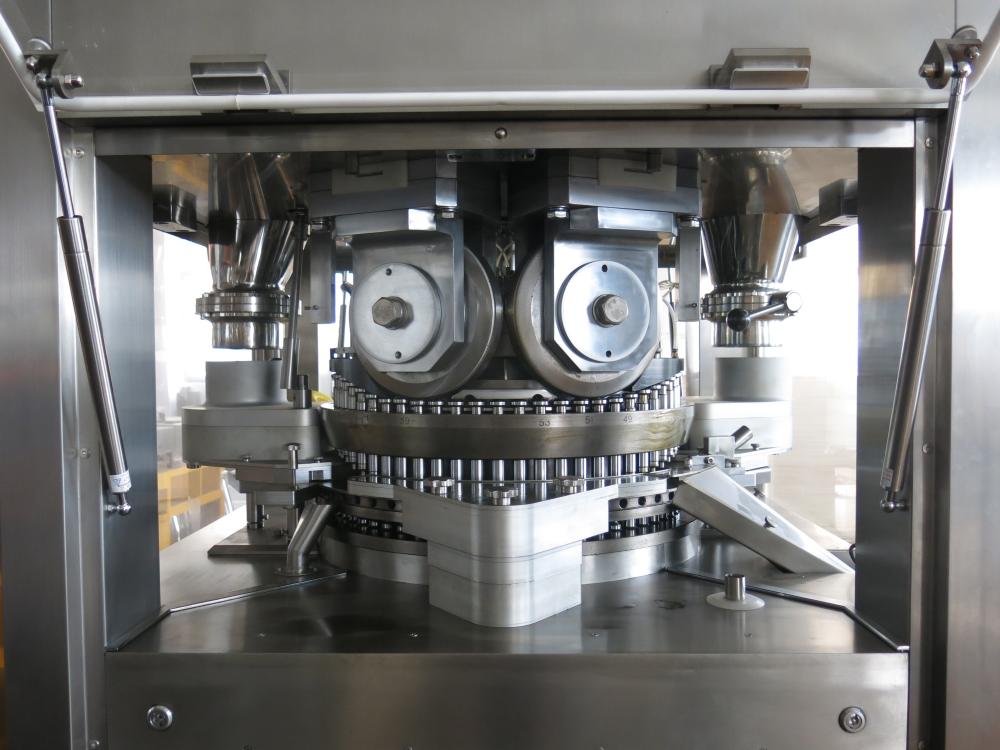

GZPK560 2-Layer fully automatic medicine tablet press with three stations compression up to 100KN

Features

● Mono and bi-layer tablet compression.

● Feeder is easy to disassembled, and the platform is easy to be adjusted.

● Four-column mechanism, low center of gravity, stable operation.

● The working area and the power area are completely separated, in compliance with FDA and CGMP standards.

● Punches head lubricated with grease oil which is more clean and meet of cGMP.

● With a 360° full-opening structure of the tablet pressing room without dead angle is convenient for cleaning, operation and maintenance.

● Gravimetric sensor of Germany Tedia Company is installed to detect the pressure, monitor the filling volume and pressure error in real time, and precisely control the tablet weight.

● Two sets of servo control filling mechanism, real-time feedback and adjustment, accurate positioning, and the adjustment accuracy of filling volume can reach 0.01mm.

Video

Specification

|

Model |

GZPK560-41 |

GZPK560-51 |

GZPK560-61 |

|

|

Number of punch stations |

41 |

51 |

61 |

|

|

Punch type |

D |

B |

BB |

|

|

EU 1’’/TSM 1’’ |

EU 19/ TSM 19 |

EU 19/ TSM 19 |

||

|

Punch shaft diameter |

mm |

25.35 |

19 |

19 |

|

Die diameter |

mm |

38.10 |

30.16 |

24 |

|

Die height |

mm |

23.81 |

22.22 |

22.22 |

|

Turret rotation speed |

max. |

90 |

||

|

Max.Output |

Tablets/h |

221400 |

275400 |

329400 |

|

1 station compression force |

KN |

100 |

||

|

2 station compression force |

KN |

100 |

||

|

3 station compression force |

KN |

100 |

||

|

Max. tablet diameter |

mm |

25 |

16 |

13 |

|

Max.filling depth 1st layer |

mm |

19 |

19 |

15 |

|

Max.filling depth 2nd layer |

mm |

6-8 |

||

|

Weight |

Kg |

4200 |

||

|

Dimensions of tablet press |

mm |

1210*1280*1960 |

||

|

Dimensions of control cabinet |

mm |

520*400*1380 |

||

|

Dimensions of electric cabinet |

mm |

1130*550*1520 |

||

|

Electrical supply parameters |

Operating voltage 220V,50/60HZ |

|||

|

Power 11KW |

||||

Highlight

1. Three stations compression all with 100KN, can press pure powder directly.

2. Three sets of pressure rollers of equal size and pressure can provide a maximum pressure of 100KN.

3. Actual pressure and filling information indicate on touch screen.

4. With automatic lubrication system.

5. The first layer tablet can be sampled when pressing double layer tablet.

6. Fully automatic tablet press and all by touch screen operation.

7. Excellent performance for difficult-to-form materials.

8. Pressure is measured directly by force transducer

9. Match up with 21 CFR Part 11

10. Low noise < 75 db

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top