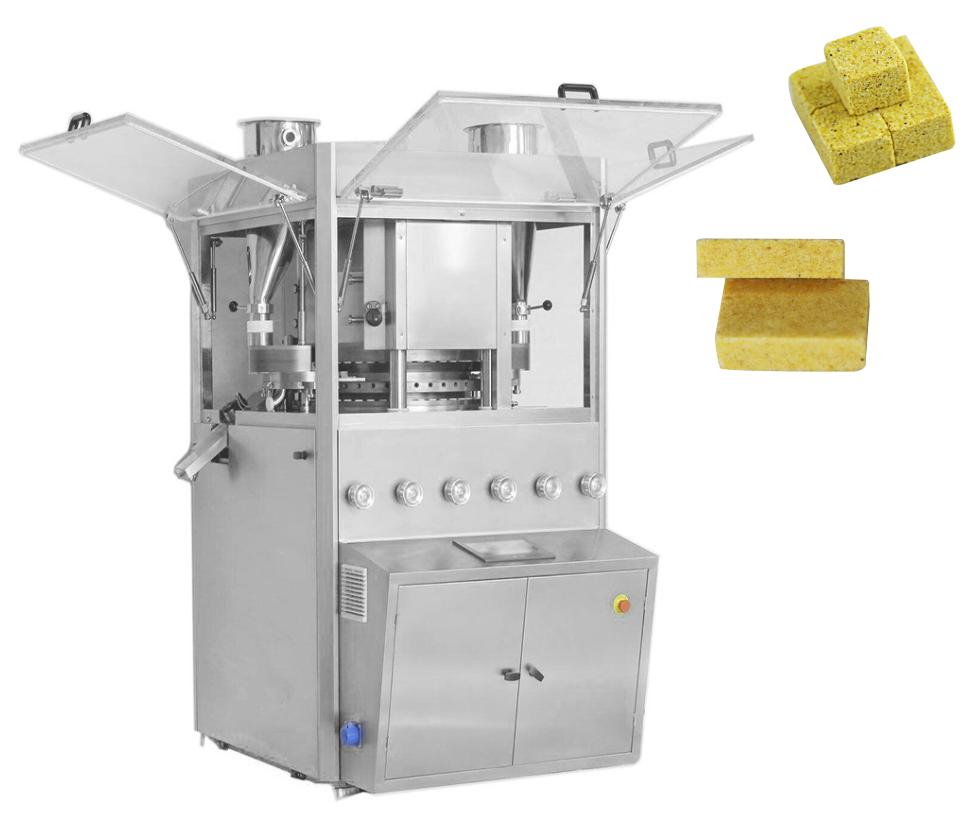

GZPK720-51 25mm salt tablet press with a large capacity up to 3 tons per hour

Features

● With SUS304 stainless steel for food grade.

● Main pressure and Pre-Pressure both are 120KN, tablet be formed by two times for a best forming.

● Double sides with force feeders that can fill evenly.

● Automatic adjust function for tablet weight, fully automatic.

● With automatic lubrication system for a continuous running.

● Tooling parts can be freely exchange for a easy maintenance.

● Main pressure,Pre-Pressure and feeding system all adopt modular design.

● The upper and lower pressure rollers are easy to clean and easy to disassemble.

Specification

|

Model |

GZPK720-51 |

|

Number of punch stations |

51 |

|

Max. Turret speed (rpm) |

50 |

|

Max. Output (pcs/h) |

306000 |

|

1 station compression force (kn) |

120 |

|

2 station compression force (kn) |

120 |

|

Max. tablet diameter (mm) |

25 |

|

Max. tablet thickness (mm) (mm) |

15 |

|

Max.filling depth (mm) |

30 |

|

Pitch circle diameter (mm) |

720 |

|

Weight (kg) |

5500 |

|

Dimensions of tablet press (mm) |

1300X1300X2000 |

|

Dimensions of switch cabinet (mm) |

890X500X1200 |

|

Electrical supply parameters |

Operating voltage 220V/3P, 60HZ |

|

Power 11KW |

Highlights

1. Force transducer for a real time pressure monitoring.

2. 2Cr13 stainless steel middle turret for anti-rust for salt material.

3. Corrosion-resistant treatment for material contact parts for salt material.

4. Fully automatic operation through touch screen.

5. Feeders are easy to disassemble which is convenient for cleaning and maintenance.

6. By servo motor for metering for a fast adjustment with a high precision.

7. Large area dust absorbing system and powerful dust collector avoid powder pollution.

8. The upper and lower turret material is QT600, and the surface is coated with Ni phosphorus to prevent rust; it has good wear resistance and lubricity.

Video

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top