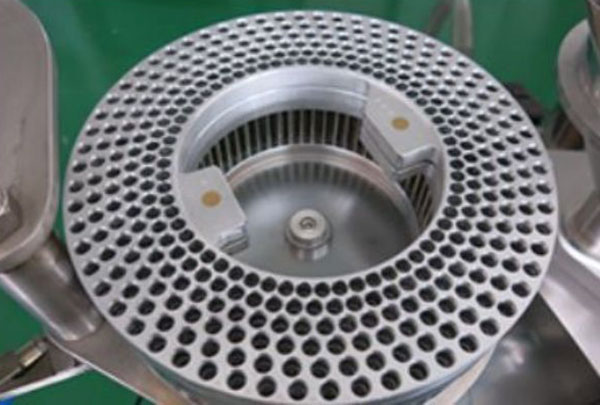

JTJ-100A Semi-automatic Capsule Filling Machine With Touch Screen Control

Features

1. Suitable to fill powder, pellets and granules in capsules.

2. Made up of stainless steel material for food and Pharmaceutical grade.

3. Operation easier and safety.

4. Hard Gelatin, HPMC and Veg capsules can be operated.

5. Feeding and filling adopt frequency conversion stepless speed change.

6. The filled capsule has no weight deviation.

7. Automatic counting and setting program and running.

8. Machine operating mechanism is done through two process.

Video

Specifications

|

Model |

JTJ-100A |

|

Suitable for capsule size |

#000 to 5# |

|

Capacity(pcs/h) |

10000-22500 |

|

Voltage |

By customized |

|

Power |

4kw |

|

Vacuum pump |

40m3/h |

|

Barometric pressure |

0.03m3/min 0.7Mpa |

|

Overall dimensions:(mm) |

1140×700×1630 |

|

Weight:(Kg) |

420 |

High light

1. Easy to operate.

2. High Output for the investment.

3. Easy for changing whole set of mold if change to another size product.

4. Vertical closing which reduces reject rates and powder spillage.

4. Modified design of powder hopper reduces time for dismantling & unloading of powder.

5. Machine is easy to clean and maintenance.

6. IQ/OQ documentation can be provided.

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top