Large Capacity Effervescent Tablet Press With Capacity 183600pcs per hour

Features

Large compression force up to 120kn for main pressure and pre pressure.

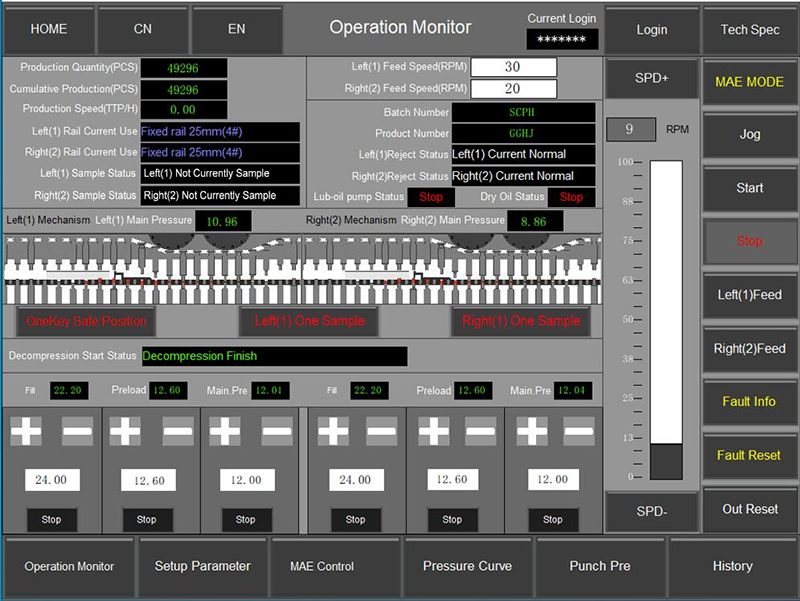

12 inches Siemens touch screen, other main components all Siemens brand.

Two layer force feeder with three impeller for both sides.

Independent operation cabinet and electrical cabinet.

Module design for each part which avoid pollution.

Excellent performance for difficult-to-form materials.

Pre-pressure equals main pressure, both are 120KN.

Servo motors for a fast adjustment of filling depth.

Multi sets filling rails, so one machine can be different thickness tablets.

Two sets of automatic lubrication system for thin oil and grease oi, control by touch screen.

Control system with smart touch screen to ensure safe and efficient operation unit. Digital PLC for monitoring and controlling with password protection.

Upper and lower punch tightness detector.

Safety interlock function.

The material contact part is with SUS316L stainless steel and middle turret is 2Cr13 stainless steel for food grade.

Compaction force monitoring and control system.

Easy clean and maintenance due to reasonable structure.

Specification

|

Model |

GZPK720-51 |

| No.of punch stations | 51 |

| Punch type |

D EU1’’/TSM1’’ |

| Main compression (kn) | 120 |

| Pre compression (kn) | 120 |

| Turret speed (rpm) | 30 |

| Max. Output (pcs/h) | 183600 |

| Max. tablet diameter (mm) | 25 |

| Max.filling depth(mm) | 18 |

| Main motor power(kw) | 11 |

| Pitch circle diameter (mm) | 720 |

| Weight (kg) | 5500 |

| Dimensions of tablet press machine (mm) | 1300X1300X2000 |

| Dimensions of operation cabinet (mm) | 890X500X1200 |

| Dimensions of electrical cabinet (mm) | 1100X500x1300 |

|

Power supply |

380V/3P 50Hz *can be customized |

Sample tablet

Video

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top