Products

-

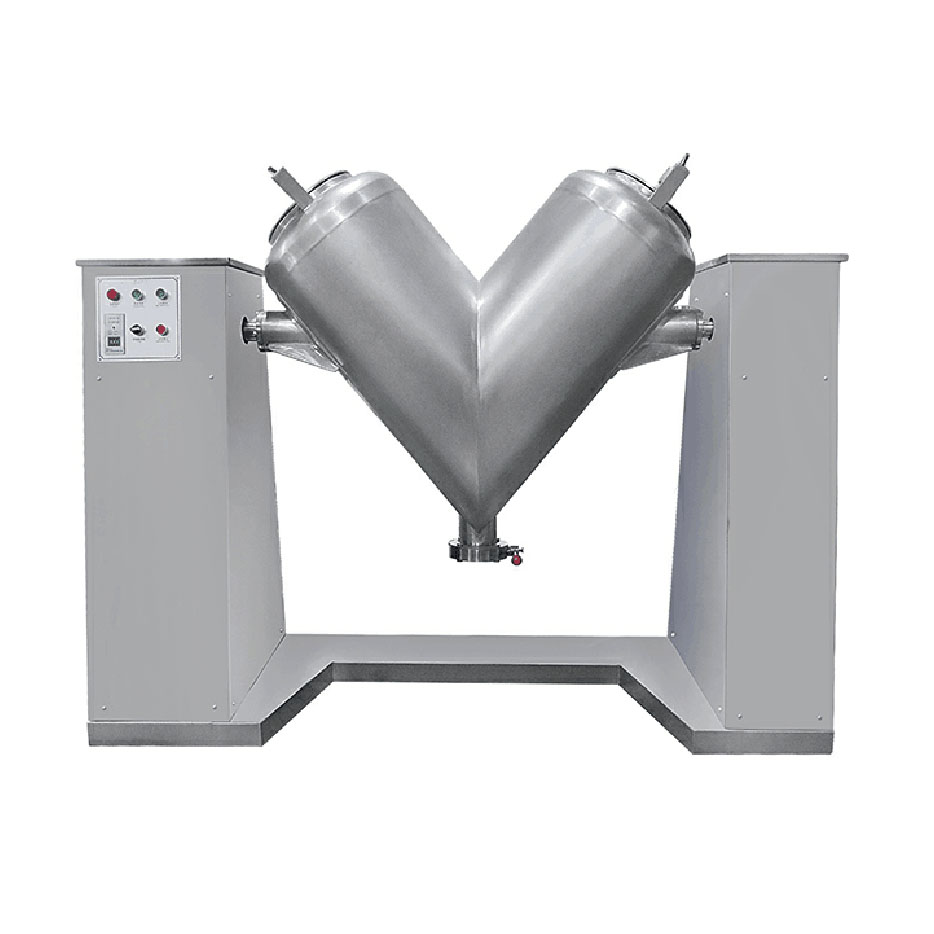

V Type High Efficiency Powder Mixer

Specifications Model Specification(m3) Max Capacity (L) Speed(r.p.m) Motor Power(kw) Overall Size(mm) Weight(kg) V-5 0.005 2 15 0.095 260*360*480 38 V-50 0.05 20 15 0.37 980*540*1020 200 V-150 0.15 60 18 0.75 1300*600*1520 250 V-300 0.3 120 15 1.5 1780*600*1520 450 V-500 0.5 200 15 1.5 1910*600*1600 500 V-1000 1 300 12 2.2 3100*2300*3100 700 V-1500 1.5 600 10 3 34... -

Single and double layer Dishwasher Tablet Press

19 stations

36X26mm rectangle dishwasher tablet

Up to 380 tablets per minuteHigh efficiency production machine capable of single and double layer dishwasher tablets.

-

Three Layer Dishwasher Tablet Press Machine-Automatic Detergent Tablet Making Solution

23 stations

36X26mm rectangle dishwasher tablet

Up to 300 tablets per minuteHigh efficiency production machine capable of three layer dishwasher tablets.

-

HD Series Multi Direction/3D Powder Mixer

Features When the machine is in operation. Because of the running actions of the mixing tank in multi direction, the flow and digression of the various kinds of materials are sped up in the process of mixing. At the same time, the phenomenon is avoid that the congregation and segregation of the material in gravity ratio occaning is avoided due to the centrifugal force in the normal mixer, So extremely good effect can be obtained. Video Specifications Model ... -

Horizontal Ribbon Mixer for Dry or Wet Powder

Features This series mixer with Horizontal tank, single shaft with dual spiral symmetry circle structure. The top cover of the U Shape tank has the entrance for material. It can be also designed with spray or add liquid device according the customer’s needs. Inside the tank there equipped the axes rotor which consist of, cross support and spiral ribbon. Under the bottom of the tank, there has a flap dome valve (pneumatic control or manual control) of the center. The valve ... -

Single/ Double/Three Layer Dishwasher Tablet Press

27 stations

36X26mm rectangle dishwasher tablet

Up to 500 tablets per minute for three layer tabletsLarge capacity production machine capable of single, double and three layer dishwasher tablets.

-

CH Series Pharmaceutical/Food Powder Mixer

Features ● Easy to operate, simple to use. ● This machine is all made of SUS304 stainless steel,can be customized for SUS316 for chemical industrial. ● Well designed mixing paddle to mix the powder evenly. ● Sealing devices are provided at both ends of the mixing shaft to prevent materials from escaping. ● The hopper is controlled by button, which is convenient for discharging ● It is widely used in pharmaceutical, chemical, food and other industries. Specifications M... -

Large-Capacity Salt Tablet Press

45 stations

25mm diameter salt tablet

Up to 3 tons per hour capacityAutomatic large-capacity production machine capable of thick salt tablets.

-

Pulverizer With Dust Removal Function

Descriptive abstract Its principle of work is as follows: when raw material entered into the crushing chamber, it is broken under the impacting of movable and fixed gear disks that are rotated in high speed and then becomes the needed raw material through screen. Its Pulverizer and duster are all made of qualified stainless steel. Its inner wall of the housing is smooth and level being processed through superior technology. Therefore it can make the powder discharging mo... -

Effervescent Tablet Press

17 stations

150kn large pressure

up to 425 tablets per minuteSmall dimension production machine capable of effervescent and watercolor tablets.

-

Double Rotary Salt Tablet Press

25/27 stations

30mm/25mm diameter tablet

100kn pressure

Up to 1 ton per hour capacityRobust production machine capable of thick salt tablets.

-

YK Series Granulator for Wet Powder

Descriptive abstract The YK160 is used for forming the required granules from moist power material, or for crushing dried block stock into granules in required size. It main features are: the rotation speed of the rotor can be adjusted during operation and the sieve can be removed and remounted easily; its tension also adjustable. The driving mechanism is totally enclosed in the machine body and its lubrication system improves the lifetime of the mechanical components. Typ...