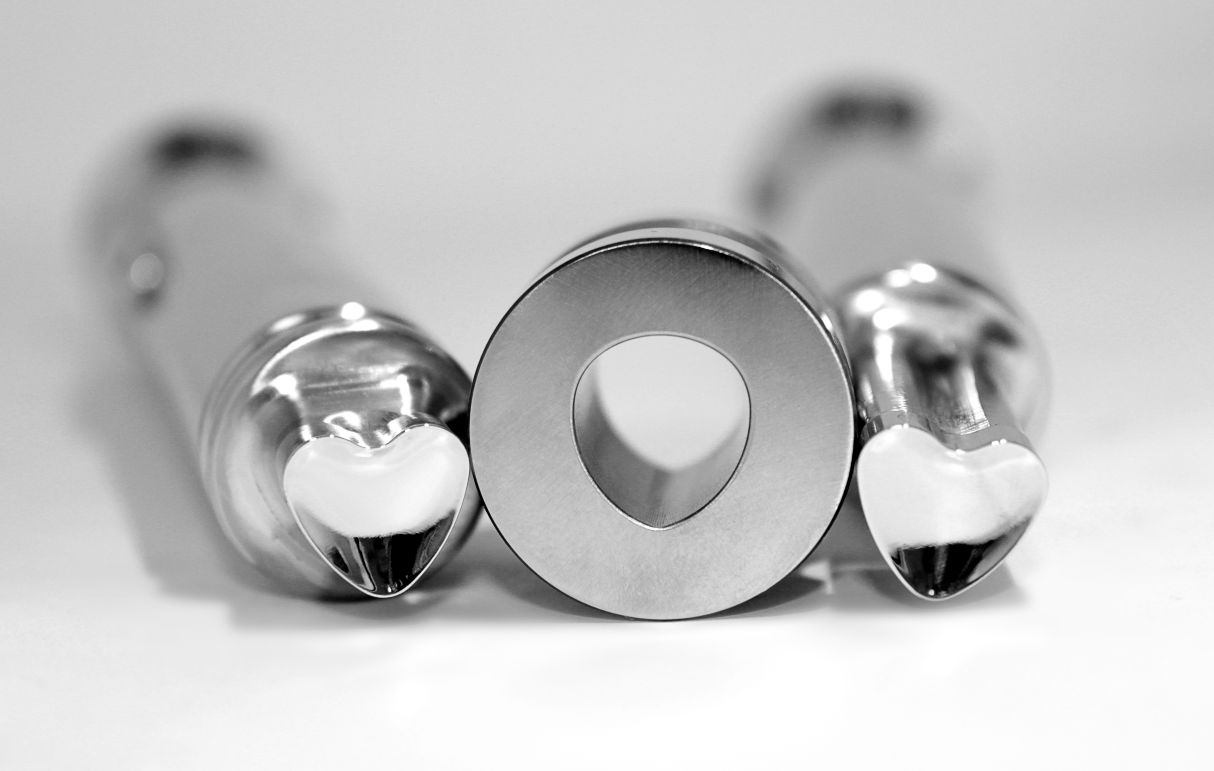

Punches & Dies For Tablet Compression

Features

As an important part of the tablet press machine, the tableting Tooling are manufactured all ourselves and the quality is strictly controlled. At the CNC CENTER, the professional production team carefully designs and manufacturers each tableting Tooling.

We own rich experience to make all kinds of punches and dies such as round and special shape,shallow concave, deep concave, bevel edged,de-tachable,single tipped, multi tipped and by hard chrome plating.

We are not simply accepting orders,but also providing overall solutions for solid preparations to help customers make the right choices.

Through detailed pre-order analysis by experienced customer service team to avoid problems. With a strict production process control and completed inspection report to ensure every Tooling can stand the test.

According to customer’s requirements, we not only offer the standardized punches and dies, such as EU and TSM,but also special tableting tool to maximize the fulfillment of customer’s needs. Different raw materials for punches and dies as well as coating, which can only be perfected with years of experience.

Top quality tableting Toolings allow a tablet press machine to make various types of tablets. Different multiple Tooling maximizes the output and minimizes the production time.

Maintenance

1. After the production is over, a comprehensive inspection of Tooling is necessary;

2. Clean and wipe the mold comprehensively to ensure the cleanliness of Tooling;

3. Clean up the waste in Tooling to ensure no waste oil in the waste box;

4. If it is stored temporarily, spray it with anti-rust oil after cleaning and put it in Tooling cabinet;

5. If Tooling will be put for a long time, clean it and put it in a mold box with diesel at the bottom.

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top