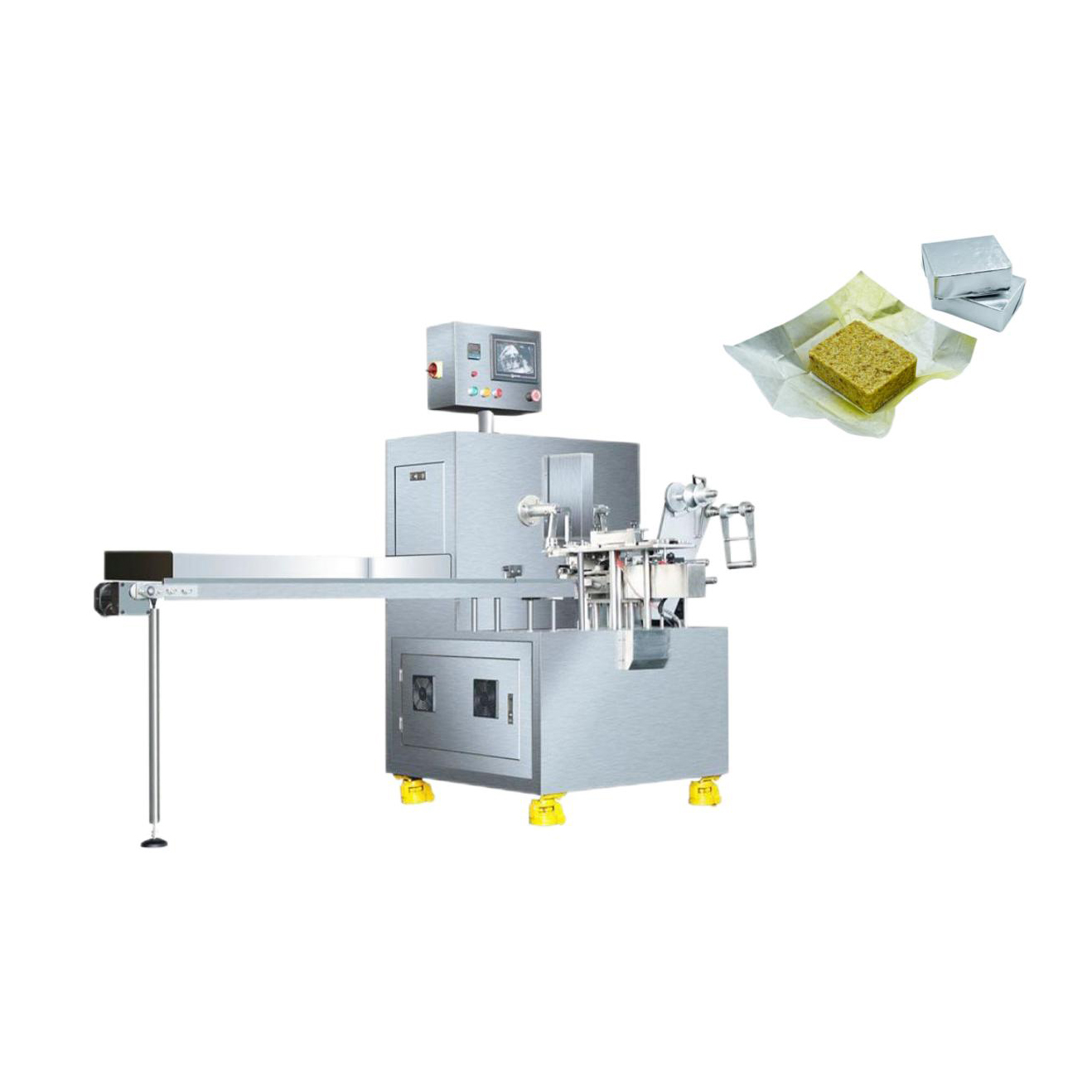

Seasoning cube boxing machine

Features

1. Small structure, easy to operate and convenient maintenance;

2. The machine has strong applicability, wide adjustment range, and suitable for normal packaging materials;

3. The specification is convenient to adjust, no need to change parts;

4. Cover the area is small, it suitable for both independent working and also for producing;

5.Suitable for complex film packaging material which saving cost;

6.Sensitive and reliable detection, high product qualification rate;

7.Low energy consumption,only need one operator;

8.Adopt PLC automatic control system, frequency control;

9.HMI operating system, automatically display production speed and cumulative output;

10.Manual and automatic selection function;

11.Various specifications can be adjusted within the range of use specifications, no need to replace parts;

12. With automatic detection system. It can automatically check out empty or not. Adopt automatic positioning and automatic rejection function for the missing cube or missing material;

13.It equipped with fault display on touch screen.Operator can know what caused the fault through that.

Video

Specifications

|

Model |

TW-160T |

|

Power (kw) |

2.2 |

|

Voltage |

Will be customized |

|

Boxing speed (box/minute) |

40-80 |

|

Box specification(mm) |

(60-120)×(30-83)×(14-43) |

|

Box material (g) |

250-300(white cardboard Or 300-350(grey backboard) |

|

Starting current (A) |

12 |

|

Full load operating current (A) |

6 |

|

Air consumption (L/min) |

5-20 |

|

Compressed air (Mpa) |

0.5-0.8 |

|

Vacuum pumping capacity (L/min) |

15 |

|

Vacuum degree (Mpa) |

-0.08 6 |

|

Overall size (mm) |

1500*1100*1500 |

|

Total weight (kg) |

1200 |

|

Noise (≤dB) |

70 |

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top