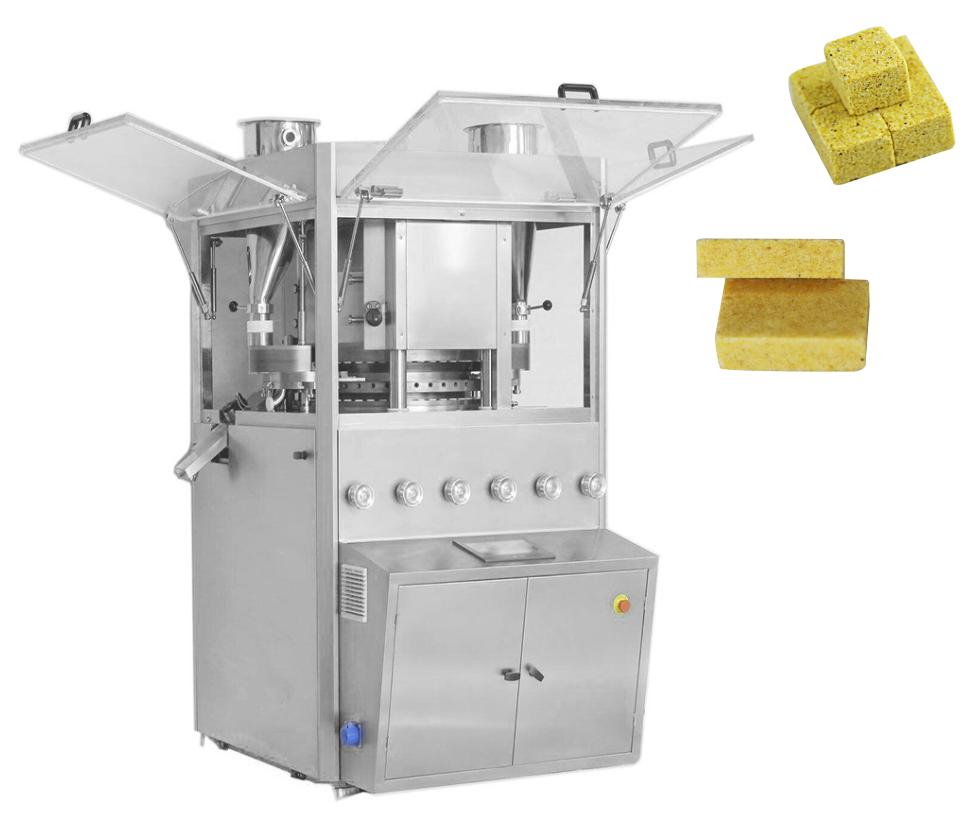

ZPT680C 3-Layer dishwasher tablet press detergent tablet press machine laundry tablet compression machine

Features

● Appearance of all stainless steel.

● Fully closed windows keep a safe pressing room.

● With three stations pressure and each station Max.pressure up to 120KN.

● Robust design and excellent reliability for durability.

● ODM service for large depth of filling for machine manufacturing.

● Speed be adjusted by inverter with brand of Danfoss.

● Pressing room be completely separated with the driven system to ensure non-pollution.

● Drive system is sealed in turbine box.

● PLC control system, easy operation through by touch screen and hand wheels.

● Protection system for the pressure overload to make machine stop when the pressure overload.

Video

Specification

|

Model |

ZPT680C-27 |

|

Numbers of punch stations |

27 |

|

Max. Tablet Pressure(kn) |

120 |

|

Max. Tablet Diameter (mm) |

45 |

|

Max. Tablet Thickness (mm) |

15 |

|

Max.Turret Speed (r/min) |

15 |

|

Max. Production Capacity(pcs/hour) |

24300 |

|

Main Motor Power (kw) |

15 |

|

Voltage |

380V/3P 50Hz Can be customized |

|

Overall Size (mm) |

1150*1150*1900 |

|

Weight (kg) |

5500 |

Highlights

● 2Cr13 stainless steel for middle turret.

● Punches material free upgraded to 6CrW2Si.

● Main motor power of 11KW.

● Middle die’s fastening method adopt side way technology.

● Top and bottom turret made of ductile iron, high-strength that handle thick tablet.

● Columns structure and double sides with pillars are durable materials made from steel.

● Each side with force feeder for materials with poor fluidity.

● Punches installed with oil rubber which avoid oil pollution.

● Turret can be equipped with dust sealer (optional).

Sample tablet

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top